How to Get your Slide Professionally Milled

It seems like today almost all new production pistols are cut for carry optics. However, many of us have older pistols around that didn’t have this option. In a previous video I covered how to mount a red dot to your handgun without geting your slide milled, but those solutions are generally temporary and certainly not meant for anything other than a range gun.

In the above video, I’m going to go over the ins and outs of working with a reputable machine shop on having your slide milled for your optic of choice. But before we go into that, let’s talk about why getting your slide cut for a direct mount is a very good idea.

Differences between various mounting methods

In another video, I covered some of the differences between mounting methods, including replacing the rear dovetail with an adapter plate, as well as cut slides with adapter plate mounting systems.

While adapter plates are great for versatility, they aren’t ideal for concealed carry due to the added height, as well as it being another potential failure point on the pistol. Additionally, they also almost guarantee that you’ll need suppressor height sights, and if you go the dovetail route you’ll lose your rear sight entirely.

The Case for Getting your Slide Milled

So this is where direct slide mount shines. The advantages are as follows:

1) It is the most stable mounting methodology.

2) There is only a single point failure.

3) Depending on your optic, you can retain standard height backup sights, negating the need for obstructive supressor height sights, but this is true for only a few red dot optics.

Indeed, direct slide mount is the best possible red dot mounting option. One of the advantages of having a pistol that isn’t optic cut is that if you to choose to get the slide cut, you can choose the specific footprint that works with your carry optic of choice.

My Experience Working with a Reputable Machine Shop

For me, I had a bone stock Glock 26. I had already invested over $100 replacing the stock sights with Trijicon night sights, which I love and reviewed in another video. I really didn’t want to swap these sights for an inferior set of supressor height sights, or throw another $100 plus on another set of trijicon sights.

Picking the right footprint

So that led me down the road of looking to get the slide milled for a red dot, and using potentially a low sitting optic like the Holosun SCS. For glock, the SCS comes in an MOS footprint pattern, meaning that it was designed to sit low on Glock MOS slides without the MOS adapter plates, allowing you to use your stock Glock sights. Indeed, holosun had a great idea here.

However, I didn’t want to get my Glock slide cut for MOS, mainly because I would be stuck with the Holosun SCS moving forward. Or I would be forced to use an adapter plate to mount anything else.

Instead, I got a killer deal on a Holosun EPS MRD closed emitter red dot, which has the Holosun 507K footprint. This is also cross compatible with Shield RMSc pattern, so there is a huge amount of optics that will fit this cut. I got this dot for $280 shipped brand new, it MSRPs for $399.

Picking an Optic and Slide Cut that doesn’t require Supressor Height Sights

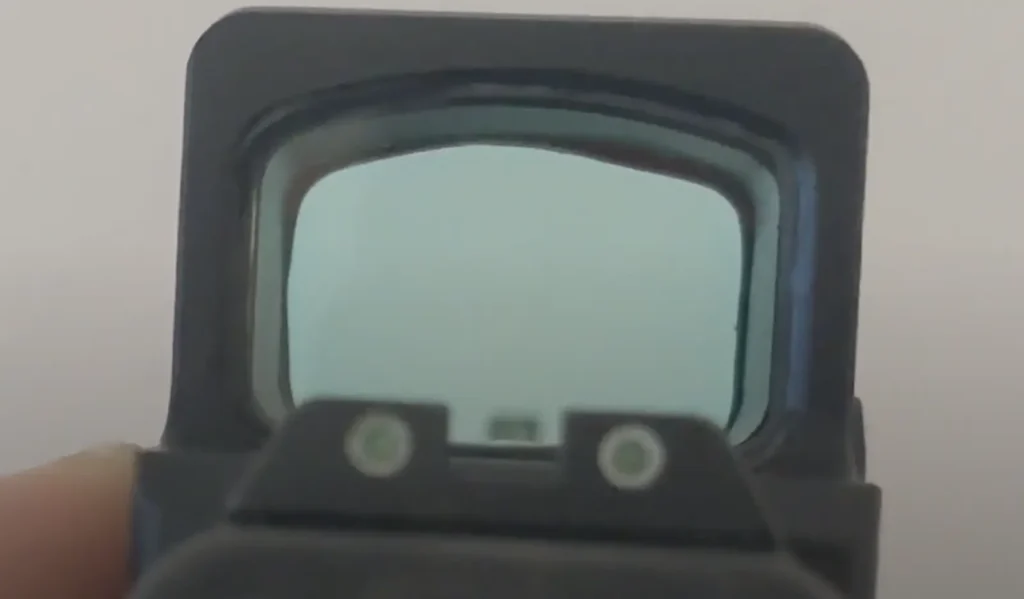

After doing some research, it turns out that the EPS sits low enough on the slide that your factory sight heights can still be usable even with the dot mount. I found later that the optic obscures a small portion of the bottom of my sights, but the irons are still more than usable. The Glock 26 with these sights I found is dead on with a combat hold anyway, so I really love this setup.

Picking a Machine Shop

I went with Maple Leaf firearms out of Texas. These guys are awesome. They are a really high quality shop to deal with. After looking at reviews for a few different places online, I went with maple leaf because I couldn’t find any bad reviews. Their website is clean and straight forward. All I had to do was pick the cut I want, as well as the model of my handgun.

I needed the pistol back as quickly as possible, because I was going to be taking a Pistol 1 and Pistol 2 course with Warrior Poet Society less than a month from making this purchase. I figured, what the heck, if there able to get it done that’d be great, otherwise I’ll shoot the classes with a different pistol. I really wanted to shoot the class with my EDC though as obviously, that is the most important gun for you to be practicing with.

Maple Leaf had Excellent Customer Service

I called Maple Leaf and the guys on the phone were great. They answered all of my questions. I explained that I was hoping to get the slide back before the classes. They gave me assurance that they would do their best to meet the timeline and that it should be doable. I was a little nervous because I didn’t have my optic yet to be able to send with the slide. I asked the guys if that would be a problem. It is best to send the optic with your slide as the shop will be able to ensure proper fitment. However, they mentioned that they have an EPS in the shop that they can line it up with so it shouldn’t be a problem.

They were also extremely friendly and I have to say they have incredible customer service. It was one of the best interactions I’ve had with any business.

So I shipped the slide off the same day, with confidence that I was in good hands. Its important that when you pack up your slide, that you send it in a hard cardboard box with plenty of padding. Maple leaf recommends that when you shake the box with it closed, you shouldn’t hear any movement. This is critical guys, slides are fragile and can be damaged during transit, so make sure to pack your slide well.

Turn Around Time for the Slide Cut was about 2 Weeks

The waiting game began. I thought about it a little bit every day. Then one day 2 weeks later, I got an email that my slide was being processed. Later that afternoon, I got the shipping notification it was in the mail.

Maple leaf shipped it back with 2-day Fedex shipping. It was back before I knew it. Maple leaf packed the slide really well. Their packaging is super high quality. They included better mounting screws than what came with my optic. They also included a few nice freebies.

The Result

The fit for the optic was perfect. It was extremely tight. Its the tighest machining I’ve seen for an optic, even including factory cut slides. My Holosun EPS slid on like butter. The slide looks like it came this way from the factory, yet its even tighter than factory tolerances. I love it, I couldn’t be happier. Maple leaf knocked it out of the park.

I didn’t opt to have my slide cerekoted because the timeline was so tight, but they did put tool black down on the milled areas. This is a good option if you want to keep the factory finish. Its important to note that tool black will not protected against corrosion, but it is a lot more maintenance as you have to keep that area greased around once a year. You also have to keep the away from moisture as much as possible. I will probably send it back to them after the class to have it cerakoted as well.

Conclusion

Overall, I got the slide back with over a week before the class begins, so I had plenty of time to get to the range and get the optic sighted in.

Maple leaf is awesome and I’d highly recommend that you consider them for this job. They make the entire process extremely easy, and they produce an incredible product.

So overall I’d highly recommend if you’re on the fence, that you spend the $115 or so and have a professional shop like Maple Leaf cut your slide. You won’t be disappointed, and the advantages of a direct milled slide pays dividends over the life of the firearm.

That’s it for today guys. We are going to be finishing out the year strong with even more helpful videos. Next week we’re going to take a look at Brownell’s Alumahyde gun finish and how to color match flat dark earth. You won’t want to miss it.